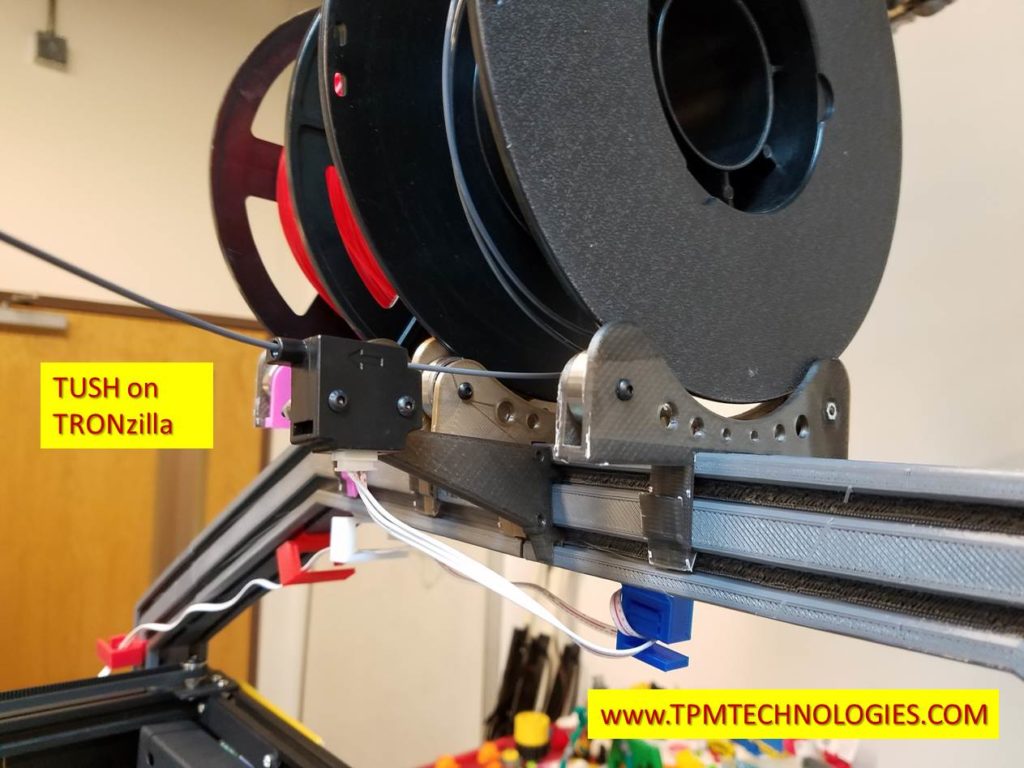

The Ultimate Spool Holder (TUSH) was adapted for supporting the direct drive conversion of TRONzilla. The project started by printing a superstructure mounted on TRONzilla using the 40×40 extrusion profile (These large 40×40 sections were printed on TRONzilla). Clips were added to hold the roller assembly in place. The friction is enough so the top needs no teeth like the original TUSH. The rollers can be slid easily along the extrusion and the weight of the spool and friction of the clips keep them to the proper spacing. Screws were added to the bearing spindles to keep the halves together and made symmetrical with a hex indent to hold the nut so only a hex driver is required for tightening. The spool rolls so easily it was necessary to add larger flanges to the outside half to keep the spool on top of the rollers as it wanted to spin out of its cradle. The extrusion profile was imported in to SolidWorks and then using the sweep function developed in the bracket you see. The TUSH model was adapted with engagement fingers in to the grooves of the extrusion profile. The original TUSH has a flat gear for setting the spacing of the spool rims. By adding a captive nut pocket the bearings are trapped more securely with a 3mm screw and nut and then the TUSH can just be slid along the profile to adjust for differing spool spacing. The extrusions were sliced in Simplify3D and printed in PLA on TRONzilla. The TUSH components were sliced in Simplify3D and printed in PLA on “Groot”, an Ender3.