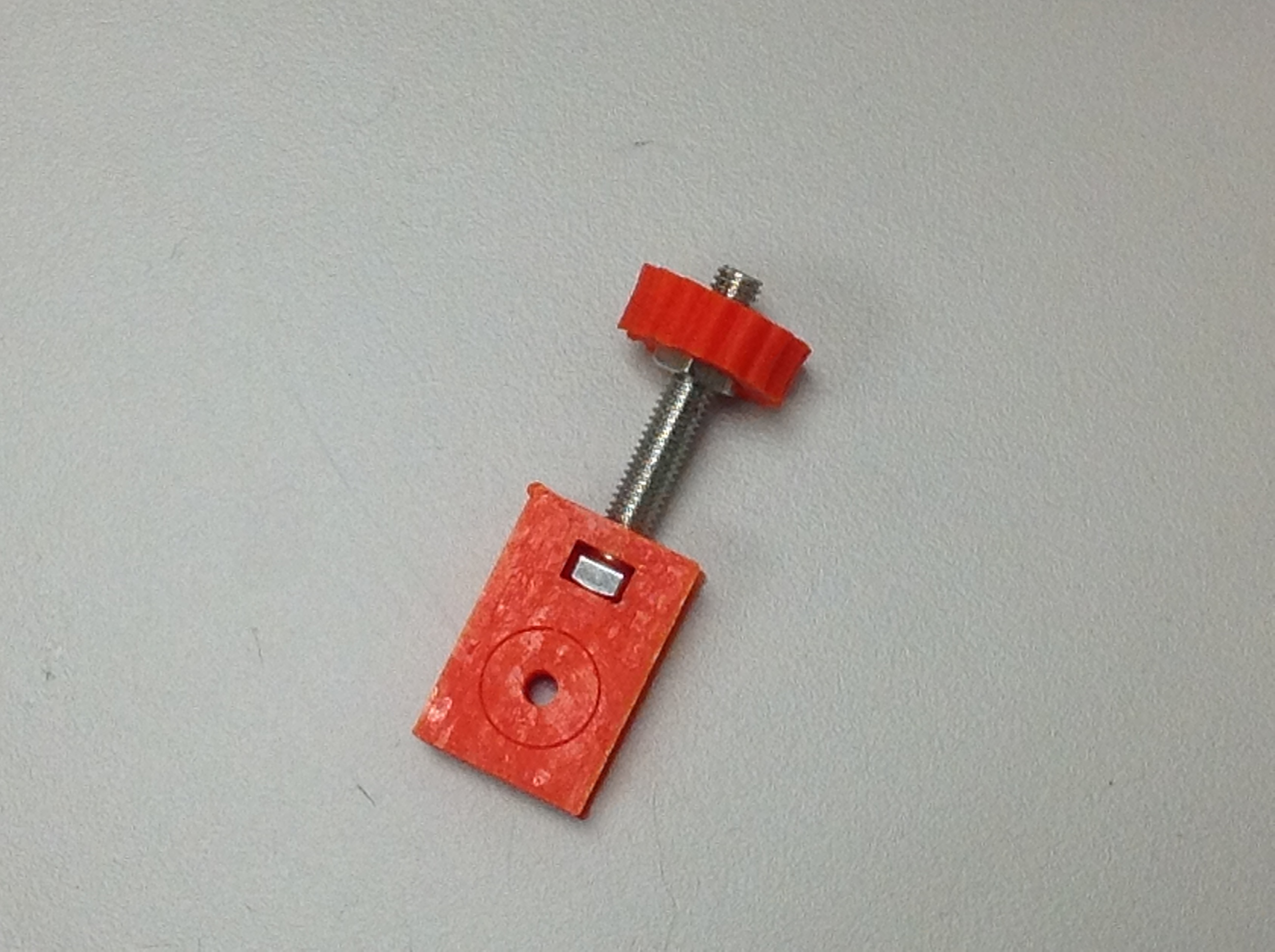

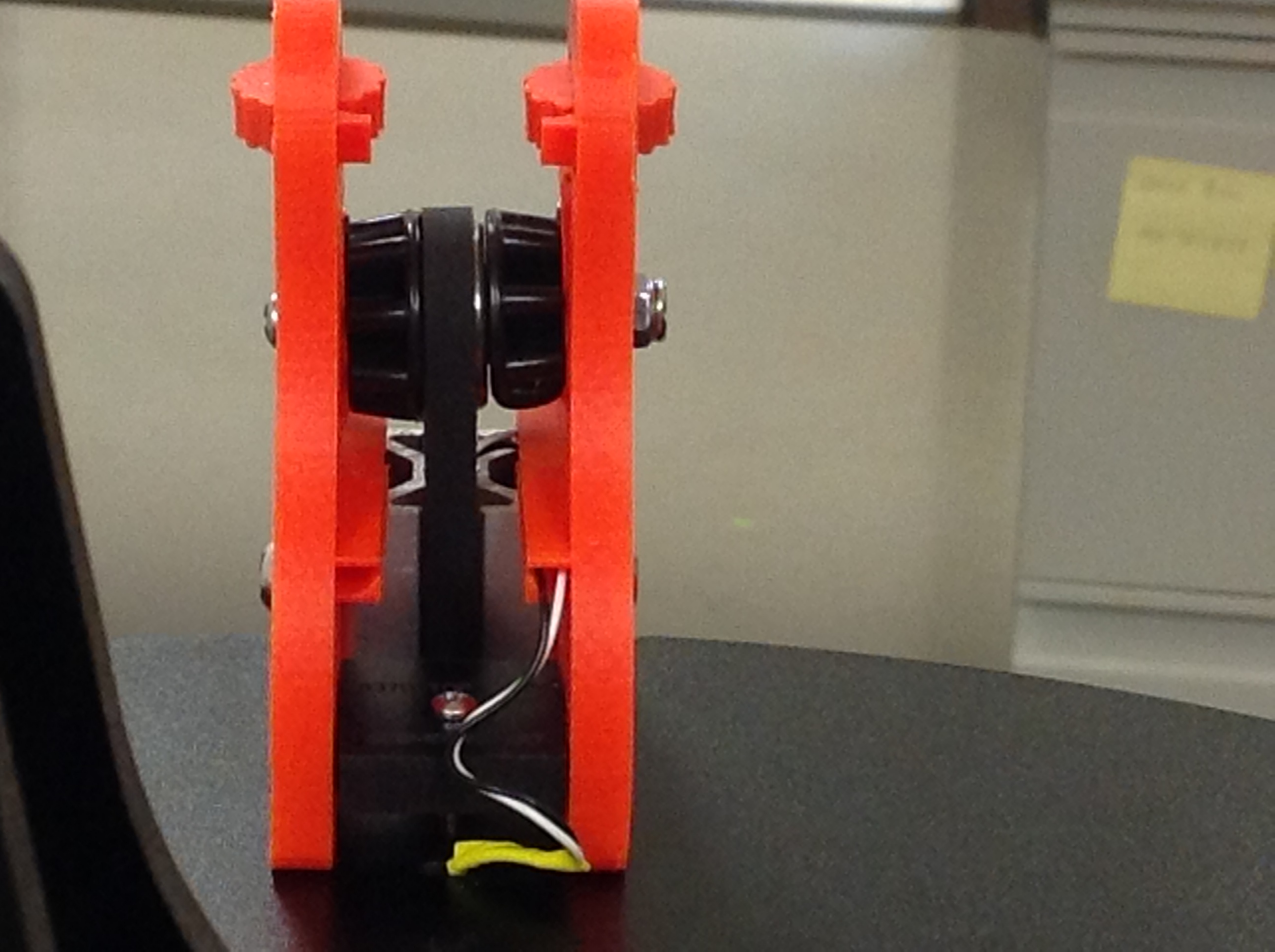

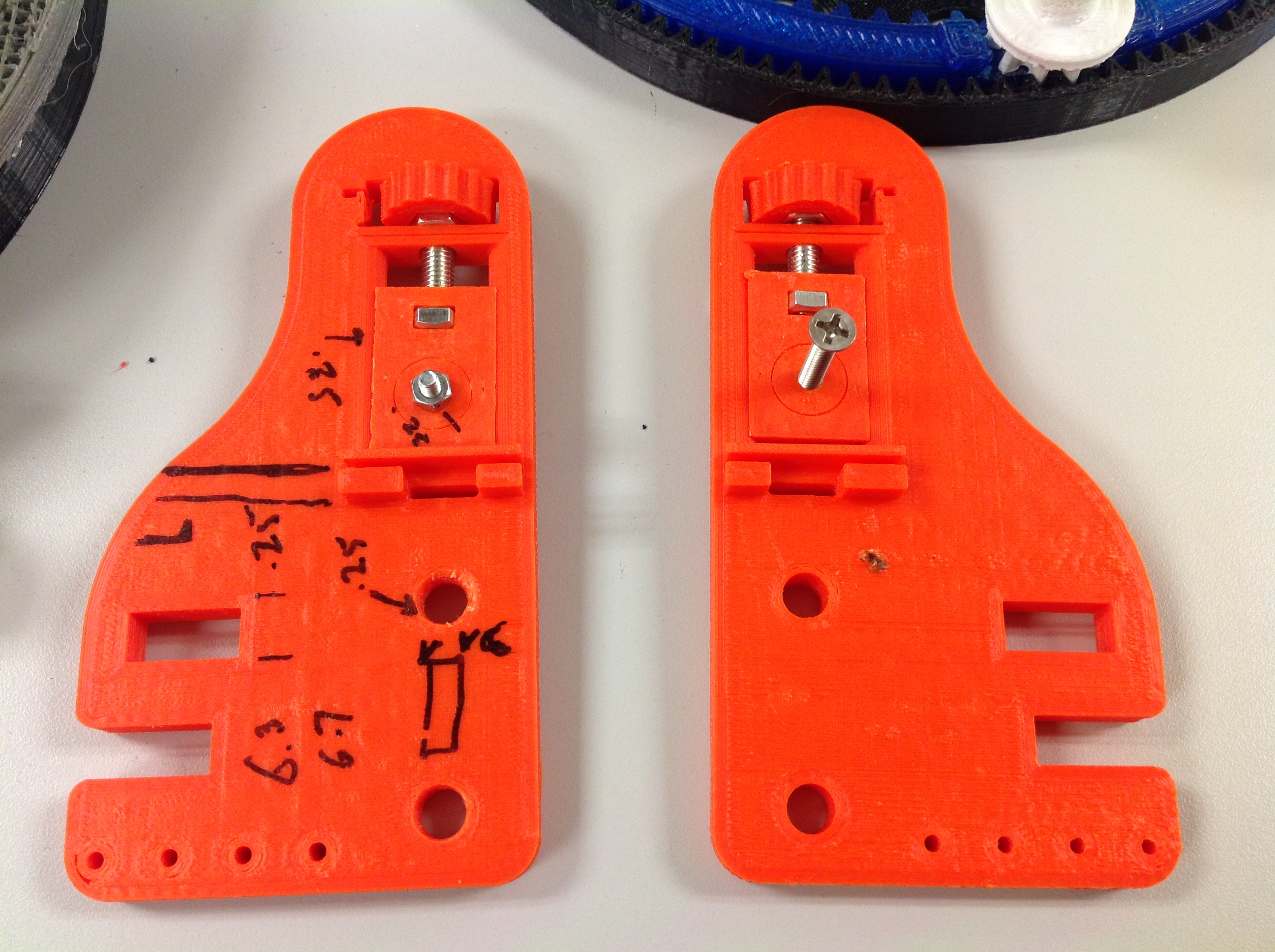

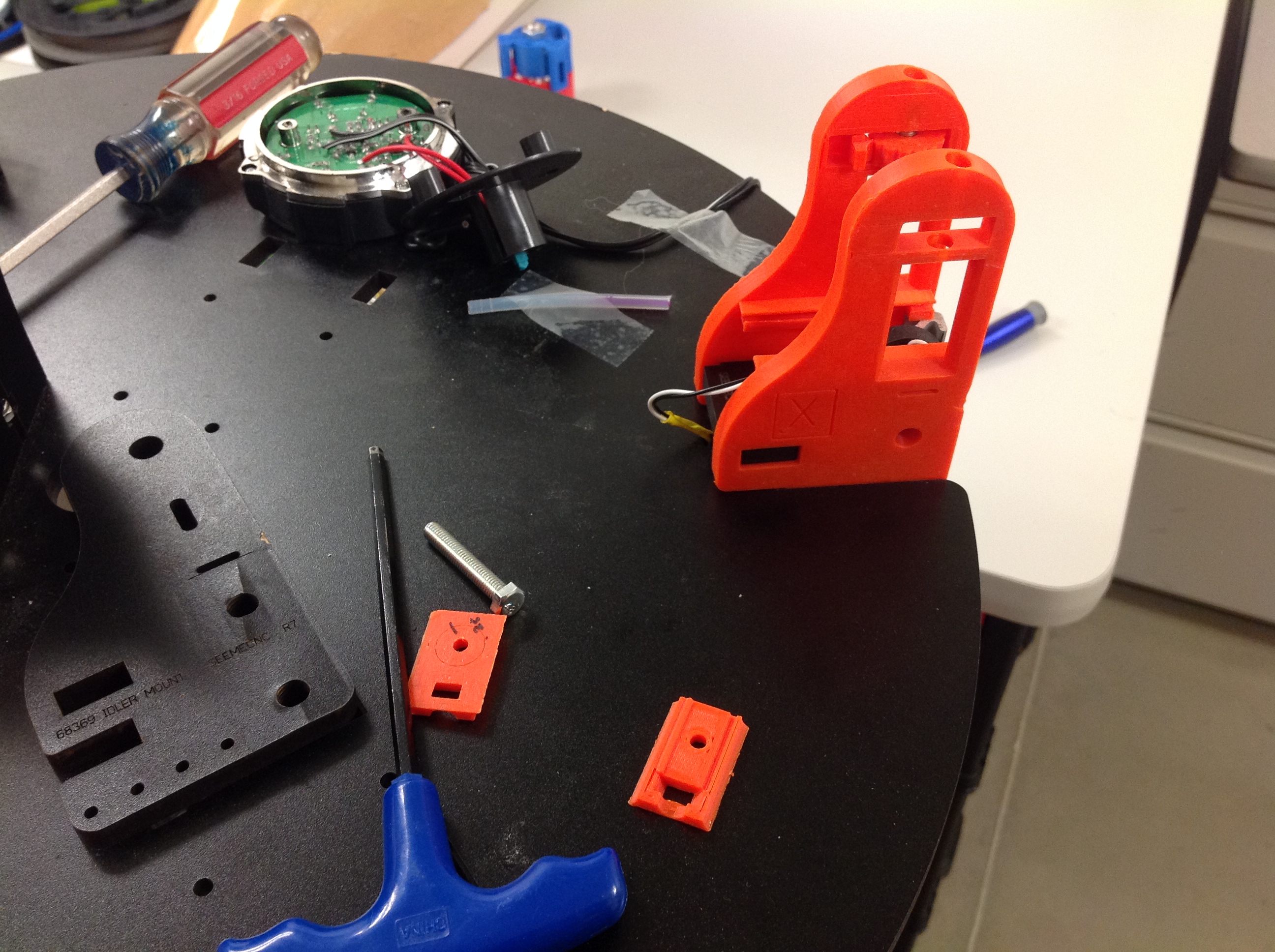

The Rostock MAX belt tensioners were OK but required tools and three hands to align the bearings, develop the tension and tighten in place. At TPM Technologies we developed a system for evenly tightening the belt from both sides and best of all, no tools required. A screw was used as a micro-adjuster. The screw head is trapped by two symmetric plates that ride up and down the plate where the nut is captured. The four traveling plates are held together with the screw that traps the bearing and spacers from the original design. The nut is encased in a knob with ridges. The ridges are locked with a spring printed into the plate. Now the belt can be tightened and equalized on both sides without tools. The design was done in SolidWorks and the parts printed in ABS on the Makerbot Replicator. The axis designation was also engrave printed into the side of the plate and each axis was color coded.

3D Printing Projects 201501 – Rostock MAX tool-less belt tensioner plates

Reply