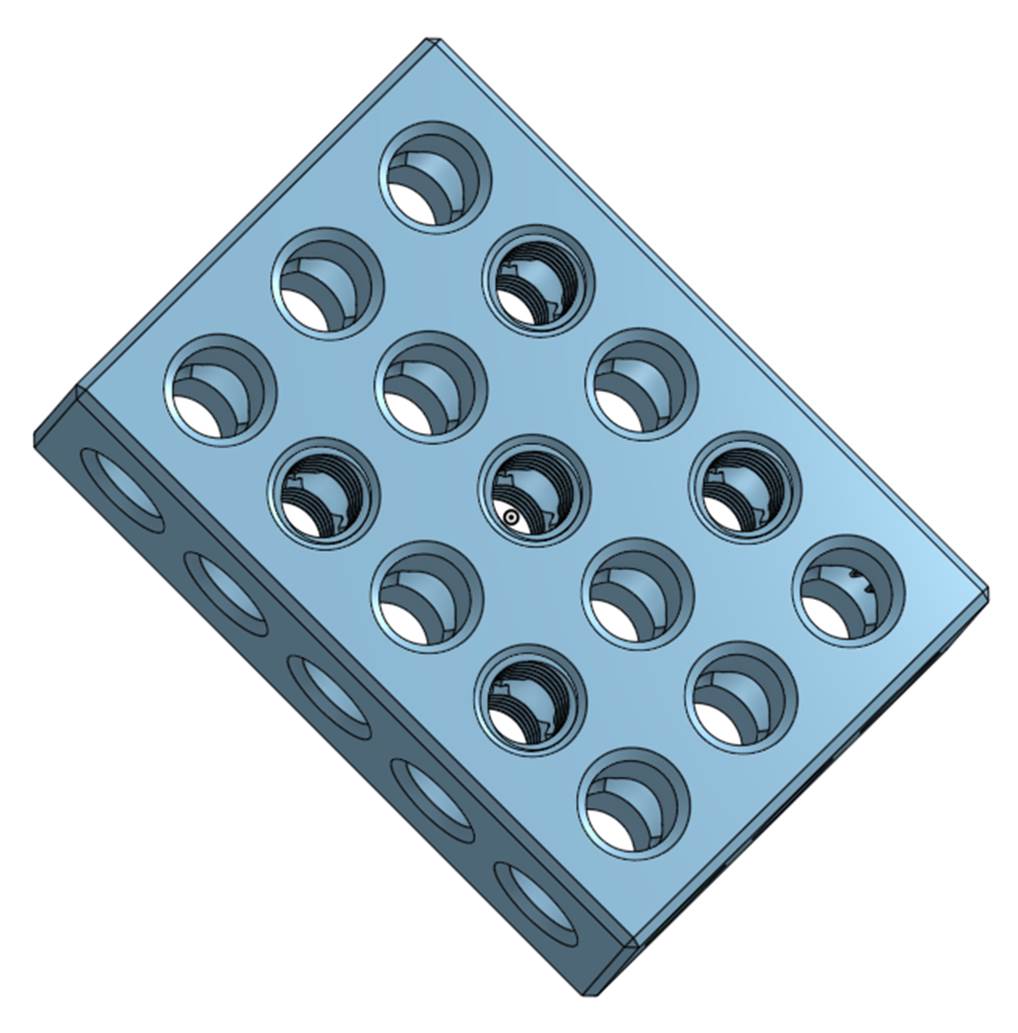

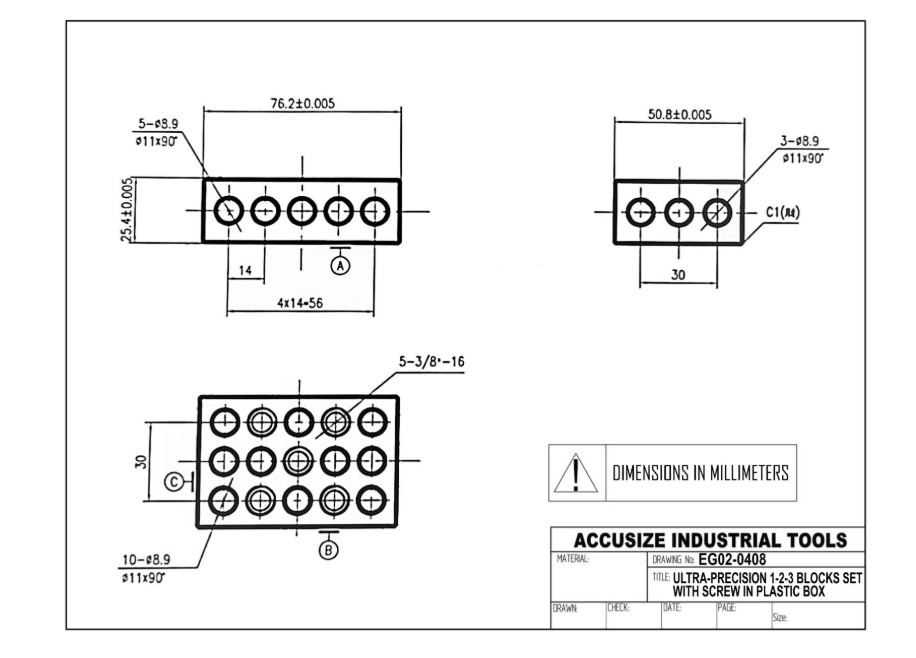

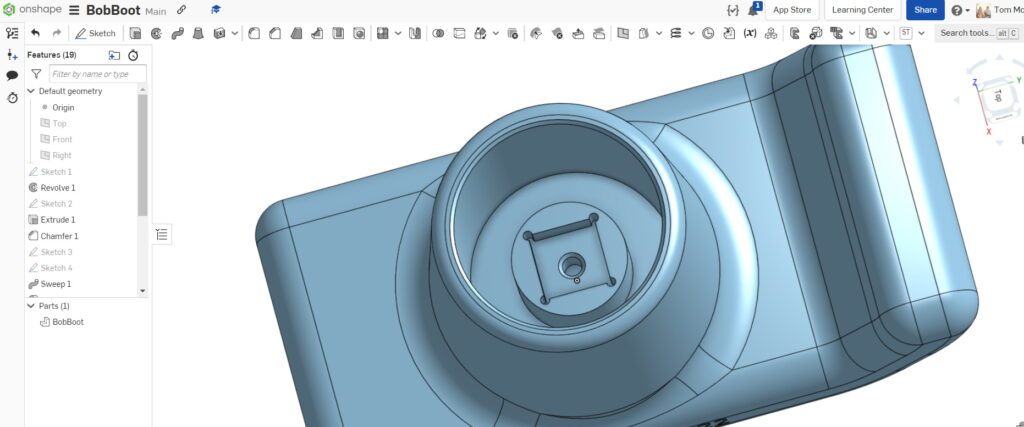

I wanted a simple but not trivial visual aid for the Onshape class and stumbled upon the 123 block as a nice prismatic practice piece. Pattering the holes got to be more involved than anyone imagined. Very good exercise for Oshape.

Utilizing an internet seach a drawing of a 123 block was found.

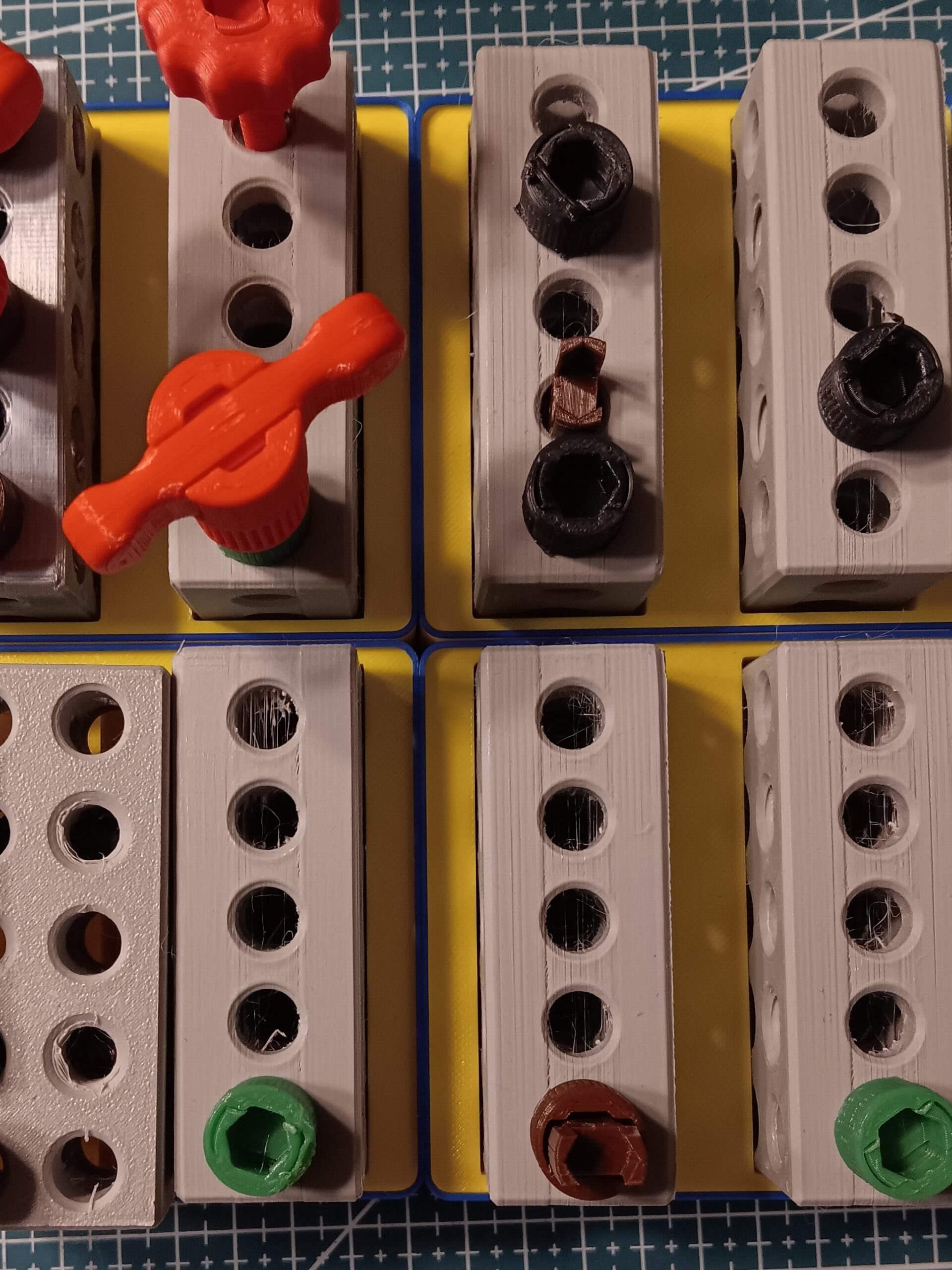

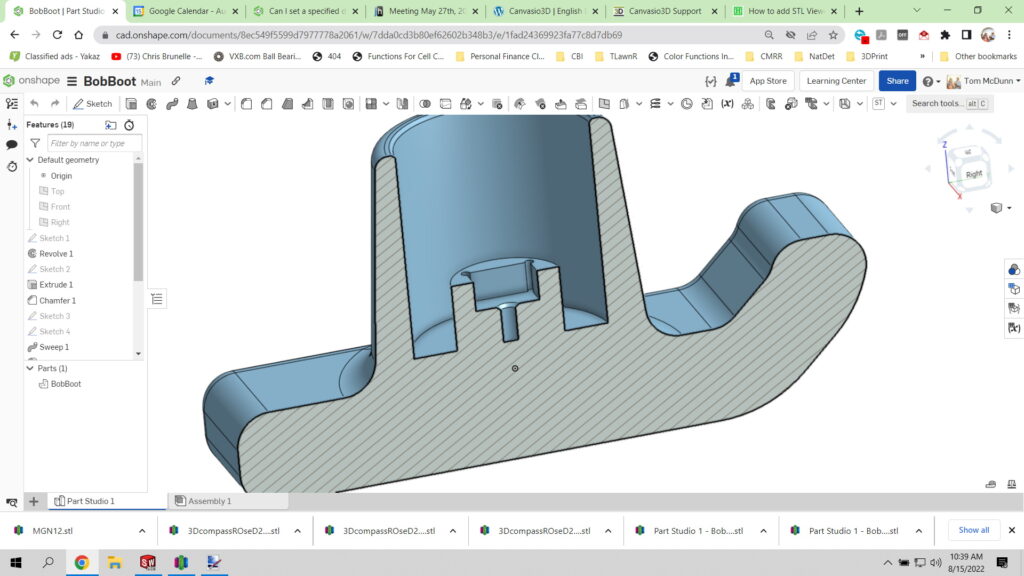

It would be nice to have fasteners to connect blocks together. To make stong threads the thread forms are printed in the XY orientation. The head was separated from the whole screw to form a T handle on the threaded portion and part of the hex socket for maximum torque. The head was then relocated for better printing orientation and a tree was added to hold them together until assembled. Configurations were established to make length selection easy.

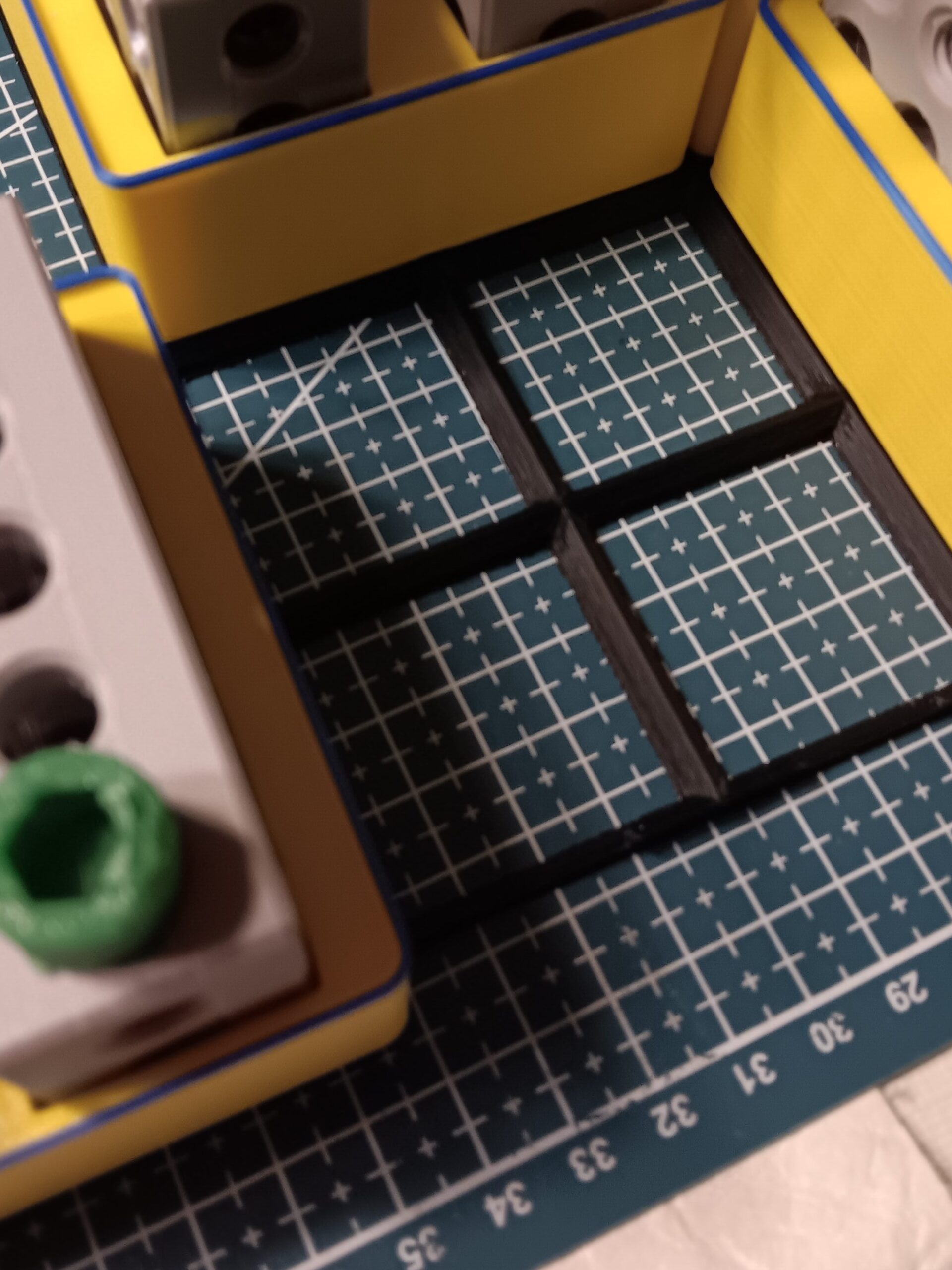

grid.

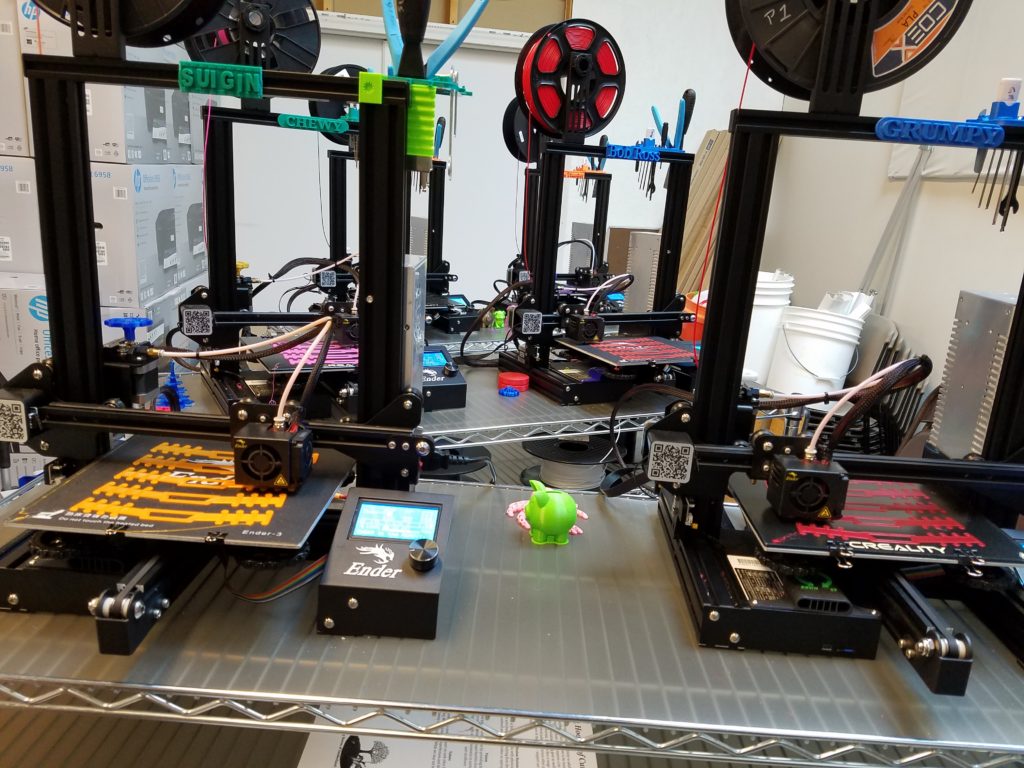

Parts were printed in PLA on the Ender3 V3 KE, Speedy-G and Tres (the 1st and 3rd refurbed KE in the lineup). The nests were printed in two color layers on the FF AD5X.Gridfinity base grids where printed on the Lost Cuz.

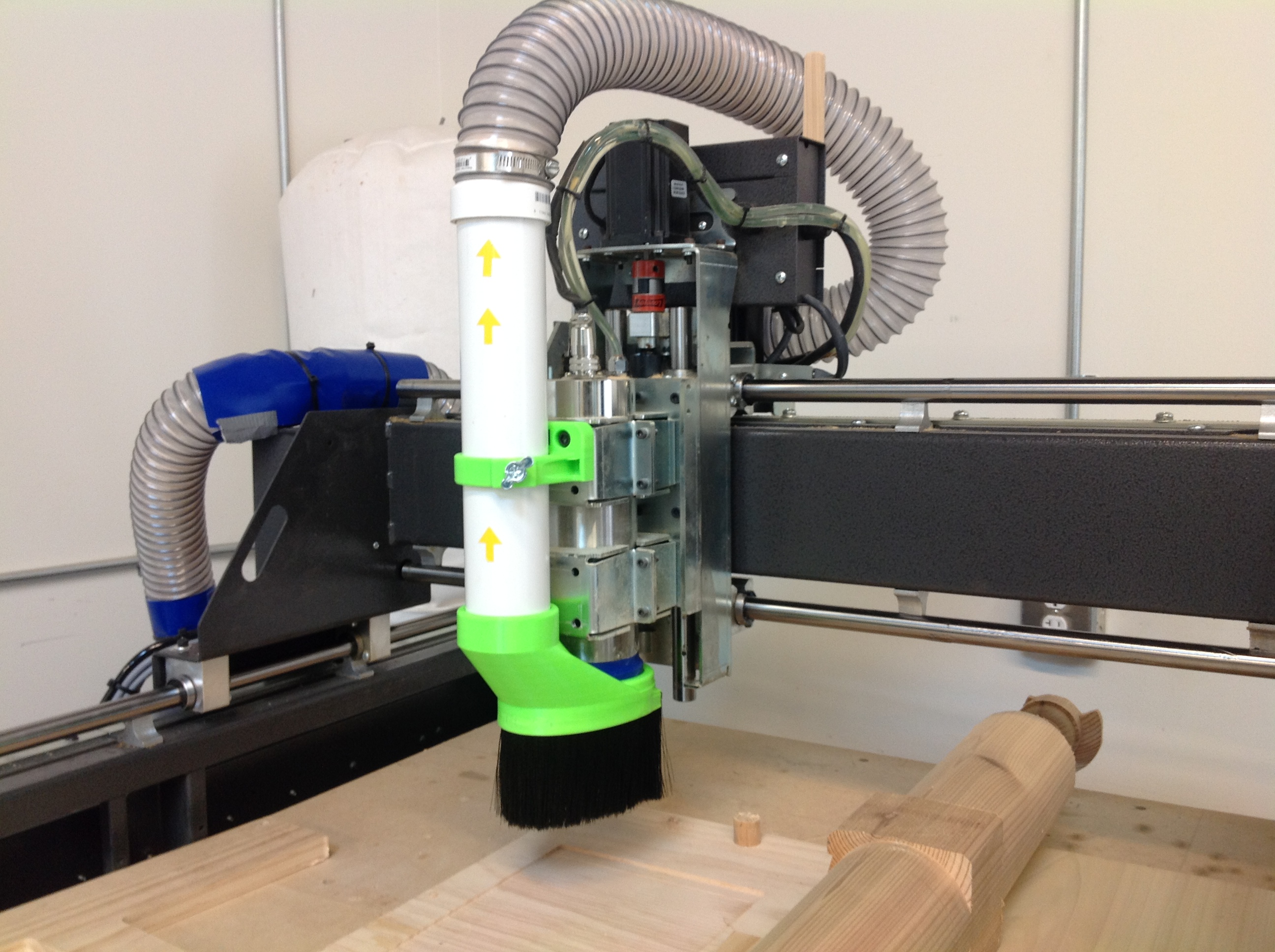

Having an effective dust collection system for a CNC router keeps the area clean and chips don’t get a change to foul up the cutting. Pipe and snout pieces were designed in SolidWorks and printed in ABS. The primary nozzle has a T-slot where a flexible brush can be inserted. The system keeps the work surface tremendously clean. Parts were printed on FlashForge Creator and Creator Pro.

Having an effective dust collection system for a CNC router keeps the area clean and chips don’t get a change to foul up the cutting. Pipe and snout pieces were designed in SolidWorks and printed in ABS. The primary nozzle has a T-slot where a flexible brush can be inserted. The system keeps the work surface tremendously clean. Parts were printed on FlashForge Creator and Creator Pro. Biki is a tweaked design based on O.T. Vinta’s Rubiks Cube solving robot. All constructed of 3D printed ABS minus some fasteners and motors. A significant change from the original was to make the legs in 3 pieces with print orientations to maximize the strength of the various parts. The carrying handle was also not part of the original design. The embossed embellishments were created in SolidWorks. Simplify3D was used to drive various build files for the FlashForge Creator and Rostock Max.

Biki is a tweaked design based on O.T. Vinta’s Rubiks Cube solving robot. All constructed of 3D printed ABS minus some fasteners and motors. A significant change from the original was to make the legs in 3 pieces with print orientations to maximize the strength of the various parts. The carrying handle was also not part of the original design. The embossed embellishments were created in SolidWorks. Simplify3D was used to drive various build files for the FlashForge Creator and Rostock Max. Bob the woodworker has a special flexible brush for spreading glue but it couldn’t reach in the crack of a biscuit slot. We developed a two filament print using Tough Ink filament for the bristles and ABS for the handle. The bristles are about 1/8 inch wide and fit easily in the biscuit groove.The design was done using SolidWorks and Simplify3D makes the work flow of two headed printing streamlined. The part was printed on the FlashForge Creator.

Bob the woodworker has a special flexible brush for spreading glue but it couldn’t reach in the crack of a biscuit slot. We developed a two filament print using Tough Ink filament for the bristles and ABS for the handle. The bristles are about 1/8 inch wide and fit easily in the biscuit groove.The design was done using SolidWorks and Simplify3D makes the work flow of two headed printing streamlined. The part was printed on the FlashForge Creator.