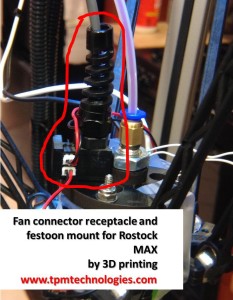

The fans for the Rostock come with tiny micro Molex connectors. The spacing is smaller than standard 0.1 inch header spacing. Wanting a sturdy end to the power festoon to the hot end a block was developed that engaged into the top mounting ring. Besides dowels that plug into the existing top plate a round cavity allows for a commercial strain relief to bring the power wire from the stationary part. A couple of square holes allow for plugging in of the micro Molex connectors. Wire was used to make pins guided by holds printed in the block. A groove to interlock the connector orientation was printed as well.

The fans for the Rostock come with tiny micro Molex connectors. The spacing is smaller than standard 0.1 inch header spacing. Wanting a sturdy end to the power festoon to the hot end a block was developed that engaged into the top mounting ring. Besides dowels that plug into the existing top plate a round cavity allows for a commercial strain relief to bring the power wire from the stationary part. A couple of square holes allow for plugging in of the micro Molex connectors. Wire was used to make pins guided by holds printed in the block. A groove to interlock the connector orientation was printed as well.

The block was designed in SolidWorks and printed in ABS. Now the fans can be plugged in and the connection of the power wire to the hot end securely fastened.